Advanced non-destructive RF measurement systems and software that reveal the true electromagnetic properties of your materials—accurately, reliably, and without damage.

✘ Your team lacks the tools or skills for deep RF analysis?

✘ Can’t get accurate data without damaging the materials?

✘ Testing delays are slowing down your R&D timelines?

You don’t have to keep struggling through these challenges. There’s a better way.

When traditional RF testing methods fall short—damaging materials, slowing down workflows, or introducing doubt—our systems provide a faster, more accurate alternative.

Here’s how we help you solve critical testing challenges:

• Preserve material integrity.

Our non-destructive RF measurement tools eliminate the need for sacrificial testing, enabling characterization of advanced composites, prototypes, and sensitive materials without compromise.

• Gain high-confidence data.

Measure complex permittivity, permeability, and dielectric properties with exceptional accuracy and repeatability—minimizing design risk and increasing validation success.

• Streamline your R&D process.

Automated systems and intelligent control software reduce testing time and human error, accelerating product development and shortening time-to-market.

• Extend your internal capabilities.

Our turnkey hardware and intuitive software empower in-house teams to perform advanced RF analysis—without requiring deep specialization.

• Simplify compliance and reporting.

Ensure traceability and meet regulatory or contractual NDT requirements with data outputs built for audit-readiness and technical reviews.

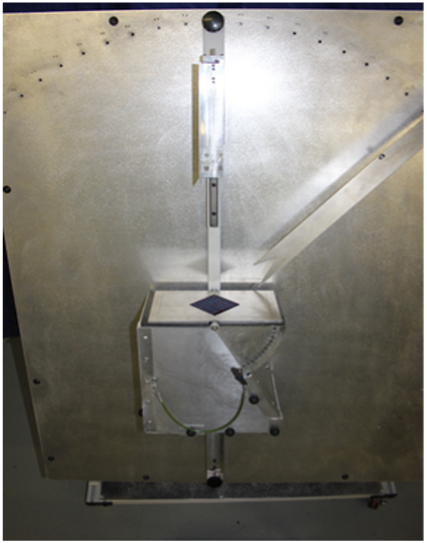

Resonators, Admittance Tunnels, Arches customizable for your product.

Material characterization for Dk, Df vs. frequency, permittivity, Ohms per square, sheet capacitance, permeability, permeance.

Online measurements, Instrument Control and automation, Easy to use Measurement GUI, timed and coordinated measurements, data collection and processing.

Empowering RF innovation across industries where accuracy, integrity, and performance are non-negotiable.

Companies like Boeing, Northrop Grumman, and others rely on our non-destructive RF measurement solutions to validate critical materials without compromising them—meeting rigorous specifications for radar, stealth, and communications systems.

From next-gen aircraft to satellite systems, aerospace innovators use our tools to precisely characterize high-performance materials—preserving their value and ensuring optimal functionality in extreme RF environments.

R&D groups exploring novel materials turn to us for the tools that enable repeatable, high-fidelity testing. Our non-destructive approach means they can test, refine, and re-test the same sample without degradation.

For high-frequency components like antennas, filters, and RF modules, material performance can make or break a product. Our systems provide the clarity and accuracy needed to refine designs, optimize performance, and ensure quality.

Government, university, and private labs trust us to push the boundaries of RF material science. Our platforms support complex experimentation and advanced modeling—without sacrificing sample integrity.

Contact us. Let’s have a conversation to find out what’s possible.

Our systems are built for precision—because your designs and decisions depend on it. With tight measurement tolerances and robust calibration routines, you get results you can trust, every time.

Unlike conventional RF testing, our methods preserve the value and structure of your materials. Whether it’s an irreplaceable prototype or a high-cost composite, we deliver the data without the damage.

We offer ready-to-use platforms—and we customize them too. Whether you need specialized fixtures, tailored frequency ranges, or integration with your existing setup, we build around your needs.

We’ll discuss your materials, measurement needs, and compliance goals to recommend the right solution.

We’ll configure and deliver the ideal non-destructive RF testing system for your specific applications.

Your team gets full training and support to start generating accurate data—fast.

Our systems can characterize a wide range of materials, including solids, liquids, composites, and thin films. We support testing of low-loss dielectrics, magnetic materials, advanced polymers, and more—across a broad frequency spectrum.

Yes. All of our measurement platforms are designed to be non-destructive. Whether you’re testing a production part, an R&D prototype, or a rare material sample, our methods preserve the integrity of the material during analysis.

We offer solutions that span from MHz to tens of GHz, depending on the application and measurement setup. Custom frequency range configurations are also available to match your project’s specific requirements.

Absolutely. Our hardware and software are modular and compatible with most standard RF equipment. We also provide integration support to help your team get up and running quickly and efficiently.

Our systems are designed for high repeatability and precision. With advanced calibration routines and data reduction algorithms, you can expect measurement uncertainty to be minimized—ensuring reliable, actionable results.

Yes. We provide hands-on training, detailed documentation, and ongoing technical support. Whether you’re new to RF material testing or have a highly specialized need, we’ll ensure your team is fully equipped to succeed.

Yes. We offer virtual or on-site demos and can run test cases on your materials to demonstrate the capabilities of our systems. Just contact us to schedule a consultation.